Marine Hardware

Boating Advice: Seacocks lead to sinkers

The Surveyor offers expert advice about seacock maintenance, avoiding sunken boats and insurance cover

The Surveyor offers expert advice about seacock maintenance, avoiding sunken boats and insurance cover

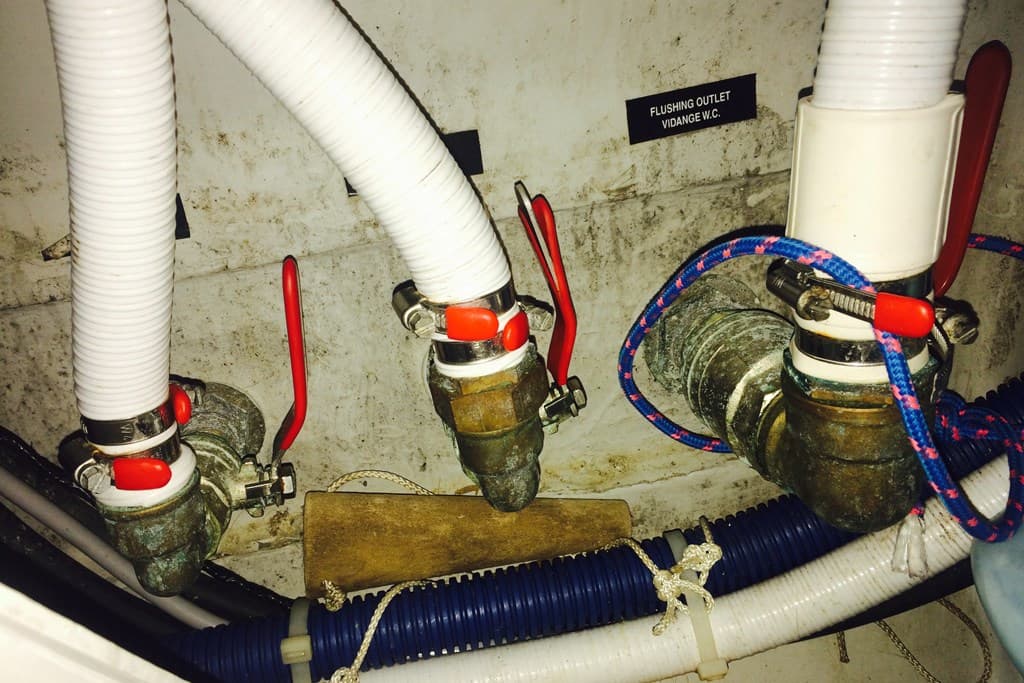

The humble seacock, stop cock, gate valve or ball valve is one of the most important items on the vessel and it is the last line of defence for keeping large amounts of sea water from flooding your vessel.

So why is it the lowest on many boat owner’s maintenance checks?

More often than not it is a case out of sight out of mind, limited access for even the simple task of operation, let alone any upkeep.

Seacocks, as I like to call them, should be at the top of your check list. Let’s face it an inch and a half toilet outlet soon floods and sinks any vessel at a rate of knots.

There are many influences that contribute to the demise of the seacock; many are made up of dissimilar metals, atmospheric corrosion, electrolysis and influences (covered in previous articles) causing the breakdown of the part.

Lack of use is a major one. They are moving parts and many don’t move that often due to the owner’s laziness.

We also have a lot of dissimilar connections in the way of elbows, joiners, tails and “Ts” all causing corrosion issues.

On toilets and exhaust outlets we have the corrosive nature of sulpha in action.

Another issue, and this raises it ugly head in a lot of pre purchase reports, are loose hose connections, once again neglected by the lazy boat owner.

Along with the seacock, the adjoining fittings and hoses should be checked frequently, as in every time you use the boat!

Ignore your seacocks and you can have a sinker on your hands.

Here are a few checks and tips that I would highly recommend in respect of seacock maintenance:

- >> Check and use your valves every time you are on your boat. This will take you less time than you think.

- >> Check the hose connection at the elbow, joiner tail, etc. Double hose clamps are recommended.

- >> Ensure your bonding system is good and properly connected.

- >> In the battle against atmospheric corrosion, a spray with a lanolin spray every six months works well. Don't forget to clean the handle after you spray.

- >> When updating the seacock, it is sometimes more economical to change the through-hull fitting. Always go for the same composition, this will eliminate a dissimilar metal issue., e.g. stainless through hull + stainless steel valve + stainless steel tails. Only 316 stainless for any below waterline fixings please.

- >> Check hose clamps and always double hose clamp

- >> Always use reinforced hose on all fittings. You will be surprised the amounts of garden hose we come across on fittings, especially on suction inlets.

- >> Always have a correct-sized timber bung attached to the seacock in case of an emergency. This is a standard in all yacht-racing categories and is something that should be mandatory on all vessels.

As I handle more and more insurance claims in my line of work, the amount of cases of submersion due to lack of maintenance is on the rise.

Bigger trailerboats are putting gear aboard these days and we're finding more and more seacocks on them, too. They need the same robust installation, maintenance and operation.

All insurance PDS (Product Disclosure Statement) state clearly that: lack of maintenance leading to failure or failure over time or affected by corrosion (and/or wording along those lines) will NOT be covered.

The best way to stay afloat and avoid that sinking feeling is to maintain your floating asset... one seacock at a time.

previous :

Know how: Thru-hulls and Seacockscategories

recent posts

copyright © 2026 XIANG YI INTERNATIONAL LTD..all rights reserved. powered by dyyseo.com

ipv6 network supported